Turbo Power Service

Turbo Power Services

HISTORY

Founded in 1985, Turbo Power Services (TPS) specialises in the supply, overhaul, upgrade and test of gas turbine fuel system components and ancillary equipment for the oil, gas, petrochemical and power generation industries.

With facilities located in the UK and UAE servicing a customer base in over 80 countries, TPS operates successfully on a global scale. Working with major original equipment manufacturers, service companies and end users of light industrial, heavy industrial and aeroderivative gas turbines.

Components are overhauled, tested and calibrated in-house at TPS’s state-of-the-art facilities, using specialist test rigs and instrumentation that replicates operating conditions and test parameters.

TPS offers rapid repair and performance testing in accordance with original equipment specification. By working closely with our customers, TPS has established a proven track record of increasing efficiency and performance of rotating equipment whilst minimising downtime during outages.

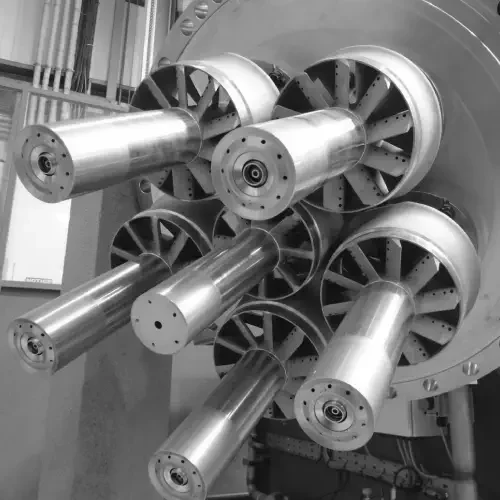

FUEL NOZZLES

Specialising in the supply, overhaul and flow testing of fuel nozzles, ranging from single fuel nozzles to complete combustor cover assemblies. TPS uses specialist in-house test rigs and instrumentation for air and liquid fuel flow testing of fuel nozzles and assemblies. All calibration is fully traceable to UKAS sources.

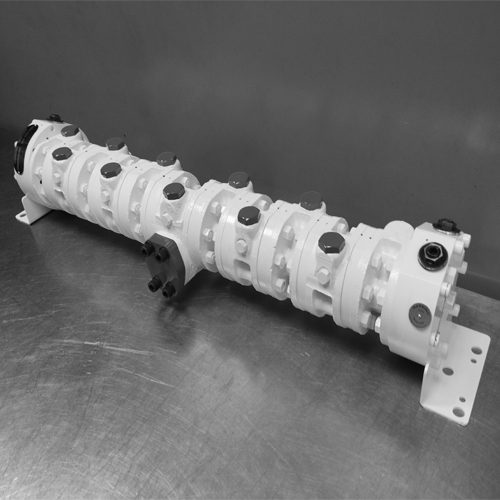

FLOW DIVIDERS

As an authorised distributor and accredited repair facility, TPS are supported by the necessary dynamic flow test equipment, replacement parts and latest procedures to ensure linear and radial flow dividers conform to the original equipment specification.

COMPRESSORS AND BLOWERS

TPS specialises in the overhaul, component repair and dynamic testing of air-end units, atomising air and booster compressors. Commissioning TPS to carry out a comprehensive service of an assembly offers significant cost saving and reduction in operational downtime when compared to the purchasing a new assembly from the original equipment manufacturer.

HYDRAULIC AND FUEL PUMPS & MOTORS

All overhauled hydraulic and fuel pumps are performance tested ensuring the acceptance criteria is achieved. As an authorised distributor and accredited repair facility, TPS are supported by the necessary dynamic flow test equipment, access to replacement parts and latest procedures to ensure that all pumps conform to the original equipment specification.

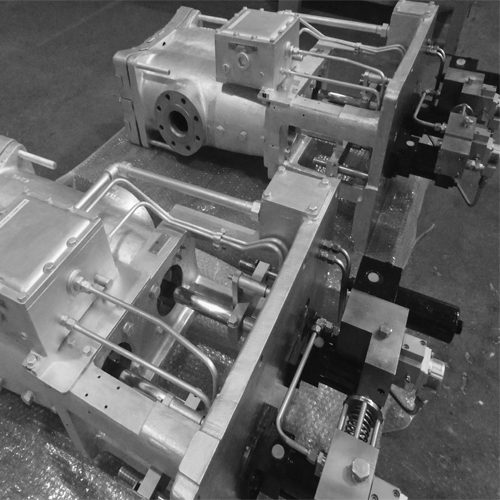

ACTUATORS

TPS specialise in the overhaul, component repair and testing of various types of hydraulic, electro-hydraulic and pneumatic actuators. Choosing TPS to perform a comprehensive service of your actuator will result in substantial cost savings when compared to purchasing a new unit from the original equipment manufacturer.

PROCESS AND CONTROL VALVES

TPS understand the critical importance of the different types of valves that are responsible for the safe running and operation of a gas turbine. TPS overhaul and test valves in accordance with the original equipment specification from every system within a gas turbine as well as associated industry sectors.

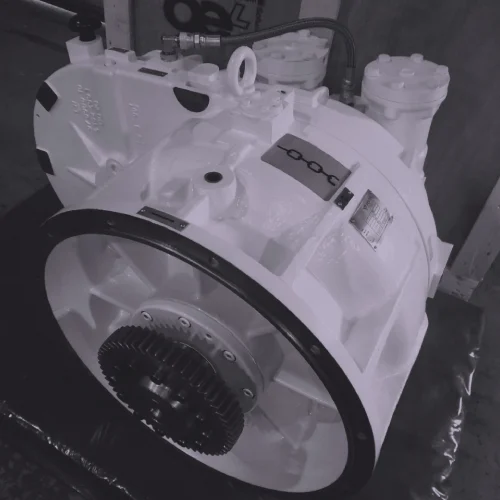

TORQUE CONVERTER AND MAGNETIC CLUTCHES

TPS offer support for the overhaul of torque converters and magnetic clutches used on gas turbines.

Our processes involve overhauling and load testing the equipment to ensure correct operation prior to return delivery. TPS guarantee that all the work carried out conforms to the original equipment specification.

Choosing TPS to perform a comprehensive service of your equipment will result in substantial cost savings when compared to purchasing a new unit from the original equipment manufacturer.

OUTAGE SUPPORT

At TPS we understand the weight of responsibility placed on end-users during an outage, our command of the operational pressure is reflected in our industry leading on-time delivery. This is something we take pride in and strive to maintain, our project teams work around the clock to ensure the critical outage deadlines are met.

We are passionate about positioning ourselves as the safest pair of hands in the industry for high value fuel system assets. We offer a complete outage service, handling the entire project package that we return certified and ready for successful commissioning.

Our philosophy is to integrate our support with the needs of the customer and our aim is to never fail to deliver and this is reflected in the satisfaction of our customers.

SERVICES WE PROVIDE:

- Project management

- Expedited lead times

- Pre-order of replacement parts

- Rapid manufacturing

- Planning and logistics support

ROPER DISTRIBUTOR

The Roper Pumps Company is a leader in innovative design and manufacture of flow dividers and pumps. The OEL-Group is the authorised distributor and accredited repair facility for all Roper Pumps products in the UK, Europe, Middle East and Africa.